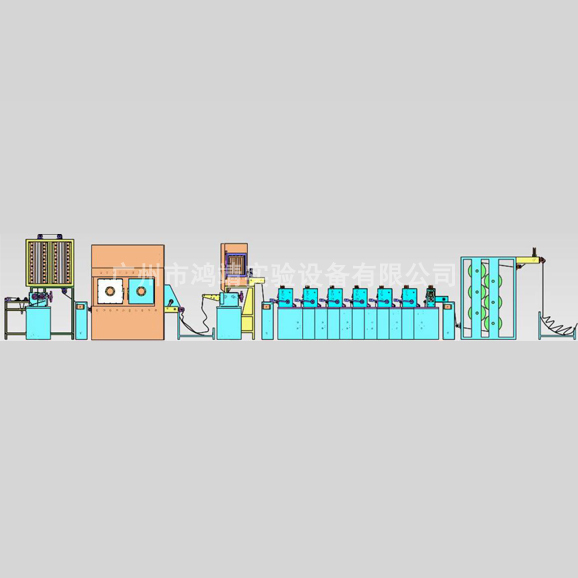

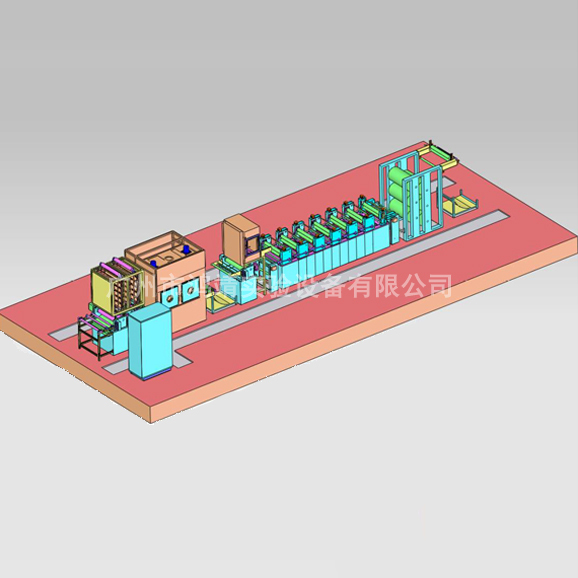

Multi-Flow High Temperature Dyeing Machine

High Temperature Dyeing Machine, Modern airflow or air atomization dyeing machines suffer from several limitations. These include high power consumption, low wind pressure, inconsistent wind distribution across pipes, heavy fuzzing of short fiber fabrics, poor color fastness, and uneven dyeing. Additionally, these machines often fail to deliver proper levelness in dyeing results.

To tackle these issues, we’ve developed a 3-in-1 design that integrates air atomization, airflow, and overflow dyeing. This design, combined with a patented double wind outlet direct-connection blower, effectively resolves the shortcomings seen in existing dyeing technologies. Not only does it enhance fabric quality, but it also significantly reduces energy usage.

Flexible Dyeing Modes: Our machine allows automatic switching between multiple dyeing modes. This flexibility directly addresses problems like high energy usage, pilling, and poor dye uniformity. Most importantly, it outperforms traditional machines when it comes to high-density fabric creases—something previous generations struggled to fix.

Full-Mode Model Capabilities: This model enables seamless switching between air atomization, airflow, and overflow dyeing. As a result, it suits both thick, tightly woven fabrics and standard knitted ones.

-

Liquor Ratio:

- Air Atomization: 1:3

- Airflow Dyeing: 1:4

Optional Pure Overflow Mode:For those needing a pure overflow setup, the machine can be configured accordingly. All three modes remain available, ensuring operational versatility.

Smart Automation Features:

- Flow meter for water control

- Automatic lint filtering

- Intelligent washing system

- Seam detection

- Proportional heating and cooling

- Dynamic drainage and more

Highly Intelligent Control: The standard configurations include: Flow meter for water supply control; Automatic lint filtering system; Intelligent washing system; Seam detecting system; Proportional heating and cooling system; Dynamic drainage and etc.

Large Capacity and Scalability:

- Max tube capacity: 400kg

- Max machine capacity: 4800kg

- Available tube configurations: 1/1, 2/2, 3/3, 4/4, 6/6, 8/8

- Volume options: 30–2400 kg

Energy-Efficient Operation

Minimum blower energy consumption is just 3.5KW per tube, which is comparable to overflow machines. Moreover, water usage is as efficient as that of airflow dyeing systems.

For Cotton Fabrics (Reactive Dyes):

- Water: ~37 tons/ton (dark shades)

- Power: ~190 KWH/ton

- Steam: ~1.4 tons/ton

- Auxiliaries: up to 40% savings

For Polyester Woven Fabrics (Disperse Dyes):

- Water: ~18 tons/ton (dark shades)

- Power: ~80 KWH/ton

- Steam: ~1.2 tons/ton

- Auxiliaries: up to 40% savings

High Quality Dyeing

Knitted Fabrics: Includes 8S–21S single jersey, 16S–21S OE yarn, 26S–50S double-sided ply yarn, TR/NR Ponte-de-roma, thick fleece, terry, and various composite fabrics.

Woven Fabrics: Includes pongee, polyester taffeta, chiffon, CEY ice silk, taslan, and nylon four-way stretch, among others.

Nylon & Synthetic Fibers: Suitable for swimwear, nylon-spandex blends, mesh fabric, lace, and delicate wedding materials.

This machine effectively overcomes the dyeing difficulties typically associated with low liquor ratio overflow dyeing.

Why This Machine?

This High Temperature Dyeing Machine is Engineered for performance and efficiency, this 3-in-1 dyeing machine combines air atomization, airflow, and overflow modes—delivering superior dyeing results across a wide range of fabrics. With ultra-low energy and water consumption, intelligent automation, and high adaptability, it offers a smart, sustainable solution for modern textile production.

Reviews

There are no reviews yet.